Smart Investments: Check Out Economical Screener for Sale

Smart Investments: Check Out Economical Screener for Sale

Blog Article

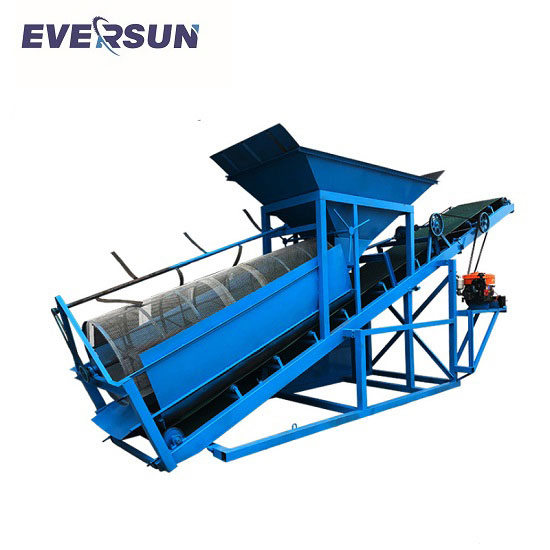

Increase Recycling Performance With High-Quality Screener Equipment

In the mission to attain greater performance in reusing procedures, one can not take too lightly the value of utilizing high-quality screener devices. These advanced testing machines provide a series of advantages that not only improve material separation capacity but additionally increase sorting rate and enhance accuracy in material category. Their advantages go past these immediate gains. With reduced downtime and upkeep requirements, these screeners make certain nonstop procedures, thereby adding to greater general recycling productivity. Yet how specifically do these equipments achieve such amazing end results? Let's explore the complexities and capability of premium screener tools to discover the keys behind their success.

Boosted Material Separation Ability

With its boosted material splitting up capacity, the high-grade screener equipment substantially enhances the efficiency of recycling procedures. This ability permits the tools to accurately separate different products based upon their dimension, shape, and density, leading to an extra streamlined recycling procedure.

Among the key advantages of the boosted product splitting up capacity is the capacity to different recyclable materials from non-recyclable waste much more properly. By successfully setting apart materials such as plastics, steels, paper, and glass, the screener tools ensures that valuable resources are not thrown away and can be reused or repurposed. This not only decreases the amount of waste sent to land fills yet additionally preserves all-natural resources, making the reusing process a lot more sustainable.

Additionally, the improved material separation capability of the high-grade screener equipment enhances the general top quality of the recycled products. By creating cleaner and higher-quality recycled products, the screener tools contributes to an extra rewarding and reliable recycling market.

Boosted Arranging Speed

One secret element of the high-grade screener tools is its capacity to manage a larger quantity of products in a much shorter quantity of time. This is enabled by the usage of high-speed motors and effective conveyor systems that can deliver products rapidly and efficiently through the screening process. By minimizing the moment it takes to sort products, the equipment boosts general recycling effectiveness.

Additionally, the high-grade screener devices includes sophisticated sensing units and sorting mechanisms that can properly determine and separate different sorts of products. These sensing units can identify variations in dimension, thickness, and shape, making it possible for the devices to promptly and precisely separate recyclables from non-recyclables - screener for sale. This not only rates up the arranging process however also improves the quality of the separated materials

Improved Accuracy in Material Category

Better accuracy in product classification is an important facet of top quality screener tools for enhancing recycling effectiveness. Precisely identifying and sorting various sorts of materials is important for efficient reusing procedures. By using advanced modern technologies and innovative testing strategies, high-quality screeners can achieve higher precision in identifying materials, leading to improved reusing results.

One of the key benefits of improved precision in product category is the ability to separate recyclables from non-recyclables extra effectively. screener for sale. With accurate classification, useful products can be identified and removed from the waste stream, minimizing contamination and increasing the total recycling return. This not just maximizes the resource recuperation potential but also decreases the amount of waste that winds up in landfills

Additionally, exact product classification enables the identification of specific kinds of recyclable materials, such as plastics, steels, or paper items. This permits targeted reusing procedures, where different materials can be refined independently, causing higher-quality recycled items. Furthermore, improved precision in material classification aids to satisfy the strict quality requirements established by recycling sectors, making certain that the recycled materials meet the necessary requirements for reuse.

Lessened Downtime and Maintenance

To ensure optimum operational performance, high-quality screener tools is created to lessen downtime and decrease the demand for regular upkeep. This is achieved through using long lasting and durable elements, progressed modern technology, and thoughtful design factors to consider.

One manner in which top published here notch screener devices minimizes downtime is by integrating self-cleaning devices. These systems aid protect against clogging and clogs, which can lead to downtime and expensive maintenance. By automatically getting rid of away debris and making sure smooth product flow, these self-cleaning functions permit the equipment to operate continuously without interruption.

In enhancement, high-quality screener tools usually consists of integrated diagnostics and keeping an eye on systems. These systems can identify potential problems and sharp operators before they intensify right into significant issues. By giving real-time details about the condition of the devices, operators can take aggressive steps to lessen and prevent break downs downtime.

Moreover, high-grade screener tools is designed with simplicity of upkeep in mind. Parts that need regular maintenance, such as belts and screens, are simple and conveniently available to change. This minimizes the moment required for maintenance tasks, allowing operators to obtain the tools back up and running rapidly.

Greater Overall Recycling Performance

One way top quality screeners boost recycling efficiency is by reducing the demand for hand-operated sorting. These devices are equipped with innovative sensors and intelligent software program that can automatically identify and separate recyclable materials based upon their form, make-up, and dimension. This removes the taxing and labor-intensive job of hand-operated sorting, enabling recycling important link facilities to refine bigger volumes of materials in much less time.

In addition, top quality screeners can manage a vast array of materials, consisting of irregularly and bulky designed items. They are designed to hold up against heavy lots and are furnished with long lasting screens that can effectively divide materials of various dimensions. This adaptability allows reusing facilities to deal with a greater selection of waste materials, optimizing their operational efficiency.

Additionally, high-quality screeners are outfitted with functions such as flexible screening settings and automated cleansing devices. These features permit operators to enhance the screening process for various materials, making certain optimal efficiency and minimizing downtime.

Verdict

In verdict, premium screener tools is essential for web link increasing reusing effectiveness. It supplies improved material separation ability, increased arranging speed, and enhanced precision in product classification.

It offers enhanced product splitting up capacity, raised arranging rate, and improved accuracy in material classification.

Report this page